Researchers from the College of Science and the College of Engineering have created a novel way to 3-D print the type of high-temperature polymeric materials commonly used to insulate spacecraft and satellites from extreme cold and heat, up to nearly 700 degrees Fahrenheit.

Previously, the multi-layered polyimide — known as Kapton — could be made only in sheets, and used as a wrap because of the material’s complicated molecular structure. If you don’t recognize the name, you know the material by sight. Kapton is the “gold foil” used as outer wrapping of spacecraft.

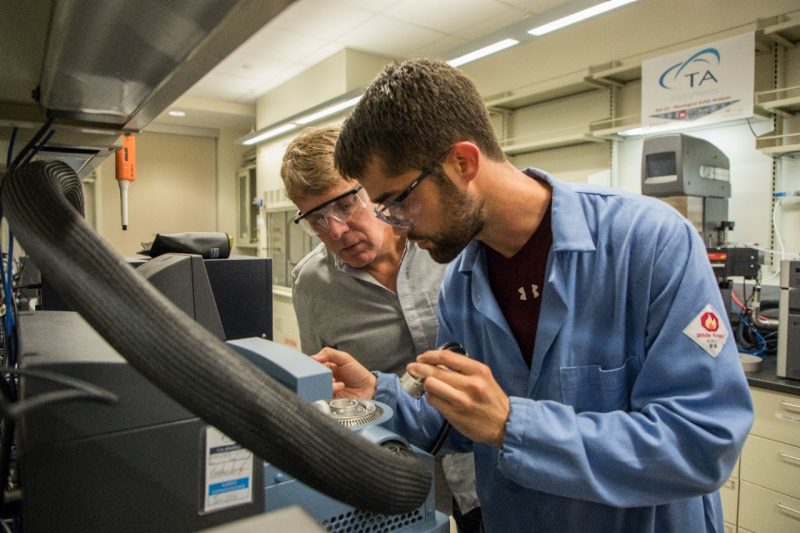

Professor Timothy Long of Chemistry and Associate Professor Christopher Williams of Mechanical Engineering, along with respective labs of graduate students and post-doctorate researchers, now have a high-performance polymer that could theoretically be used in any shape, size, or structure. The same material can be found in cell phones and televisions.

“We chose a fairly ubiquitous high-temperature and high-strength polymer because we wanted to enable a rapid impact on existing technologies,” Long said.

One improvement: Under post-doctoral researcher Jana Herzberger, the team has discovered that commercially available polyamic acids can be readily converted to a printable composition upon treatment with a photo-active base.

“We can now prepare a printable composition without the need for complex synthetic steps,” Long said. “The process is significantly more ‘green,’ meaning less environmentally harmful reagents are needed and fewer solvent intensive steps are required.”

Long has said a priority in his lab is to create greener, that is, more-earth friendly materials.

Read more about the project.